Organization: Jorawar Engineers

Expertise: Electrical Safety Audits | Thermography | Predictive Maintenance

Report Reference: JE/TA/2025/XXX

Client: Confidential (Industrial Facility)

Location: India

Date: June 2025

Case Overview

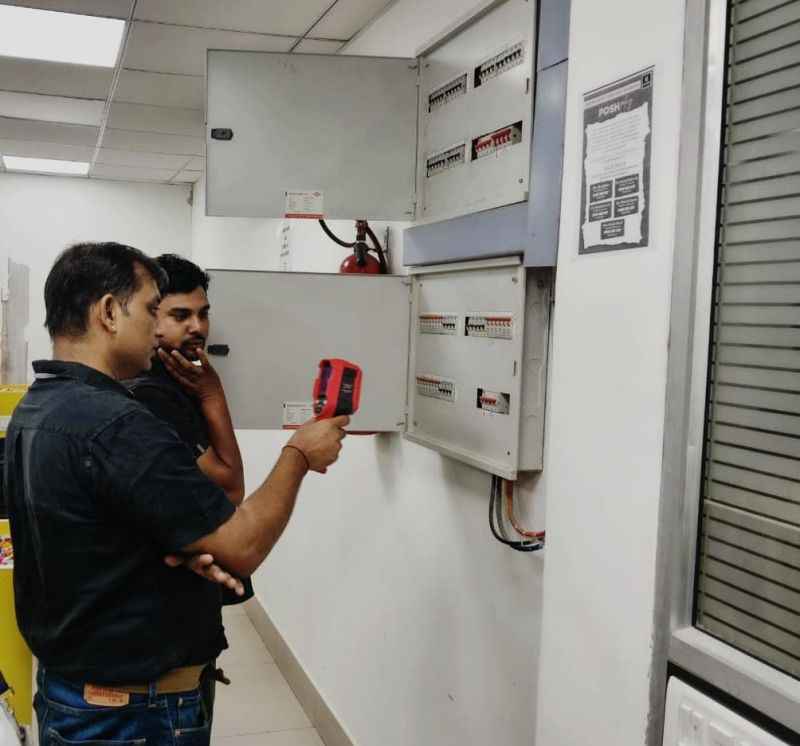

An industrial facility engaged Jorawar Engineers to carry out a comprehensive Thermal Imaging Analysis of its Low Tension (LT) electrical distribution system. The primary objective of the study was to proactively identify abnormal heating conditions, enhance electrical safety, and reduce the risk of fire or unplanned system failures.

The assessment was conducted on live electrical systems to ensure realistic operating conditions and accurate identification of potential electrical risks.

Objective of the Study

The objective of this thermal analysis was to perform live, non-invasive infrared thermography on the LT distribution system to:

- Detect abnormal temperature rise and hotspots

- Support predictive maintenance planning

- Mitigate fire and electrical safety risks

- Improve system reliability and operational continuity

Methodology

The thermal assessment was conducted using industry-accepted thermography practices:

- Inspection Technique: Infrared Thermography (Non-contact)

- Equipment Used: Handheld Thermal Imaging Camera

- Operating Condition: Live load inspection (no shutdown)

- Ambient Temperature: Approximately 37.3°C during inspection

The inspection covered LT panels, cable terminations, and critical electrical interfaces under actual operating conditions.

Key Observations

During the inspection, a critical abnormality was identified at a cable termination point inside the LT distribution box.

Observed Parameters:

- Maximum Temperature Recorded: 115.9°C

- Condition Identified: Localized overheating at the cable termination

Initial Assessment:

The elevated temperature indicated a potential loose connection or circuit overloading, posing a serious electrical and fire risk if left unaddressed.

Thermal images and corresponding visual inspection photographs were captured to support the findings.

Risks Identified

The observed overheating condition presented multiple operational and safety risks, including:

- Fire hazard due to insulation breakdown or sparking

- Accelerated degradation of cables and termination points

- Increased likelihood of unplanned downtime or system failure

- Higher energy losses caused by increased electrical resistance

Root Cause Analysis

Based on thermal patterns and site observations, the probable root causes were identified as:

- Loose or improperly tightened cable terminations

- Corrosion or oxidation on contact surfaces

- Circuit overloading or unbalanced load distribution across phases

Recommendations

Immediate Actions

- Isolate and shut down the affected circuit

- Re-tighten or re-terminate loose cable connections

Corrective Maintenance

- Clean all terminal contact points

- Apply high-conductivity, electrical-grade contact grease

Preventive Measures

- Conduct thermal imaging inspections at least twice a year

- Schedule periodic torque checks during routine maintenance

- Ensure proper load balancing across all electrical phases

Fire Safety Controls

- Place Class C fire extinguishers near electrical panels

- Install temperature monitoring alarms on critical circuits

Scope of Work Executed

- Collection of preliminary data from client site

- On-site thermography inspection and scanning

- Preparation of draft technical report

- Client review and feedback incorporation

- Submission of final thermal analysis report

- Optional post-rectification thermography verification

Reference Standards

The assessment was conducted in alignment with internationally recognized standards, including:

- NFPA 70B – Standard for Electrical Equipment Maintenance

- NETA Guidelines – International Electrical Testing Association

Benefits of Thermography Testing

- Proactive Maintenance: Early fault detection prevents costly failures

- Improved Safety: Reduces fire and electrical shock risks

- Cost Savings: Avoids reactive repairs and extended downtimes

- Non-Invasive: Performed without interrupting operations

- Efficient: Enables rapid inspection of large electrical systems

Application Areas

Thermography testing is applicable across:

- LT panels, power distribution boards, and switchgear

- Motors, generators, and pumps

- Transformers, circuit breakers, and cables

- Lighting systems and control panels

- Busbars, fuses, and electronic components

Conclusion

The thermal imaging study conducted by Jorawar Engineers successfully identified critical overheating within the LT distribution system. The insights obtained enable the client to take timely corrective and preventive actions, significantly enhancing electrical safety, operational reliability, and compliance with maintenance best practices.

Survey Conducted By:

Jorawar Engineers

Electrical Testing | Fire Safety | Green Building | O&M

📞 +91 94141 35435 | +91 70168 03127

📧 info@jorawarengineers.com | naresh.purohit@jorawarengineers.com

🌐 www.jorawarengineers.com